* SERVICEABILITY:

Obsolete Clutch/Brake

Costly Parts

Parts Unavailable

Difficult to Service Clutch/Brake

Clutch/Brake Requires Frequent Maintenance

* FASTER STOP TIME:

Shorter Safety Distance

Better Fault Protection

* CHANGES IN OPERATION:

Increased Tonnage

Increased Single Stroke Operation

Increased Continuous SPM Operation

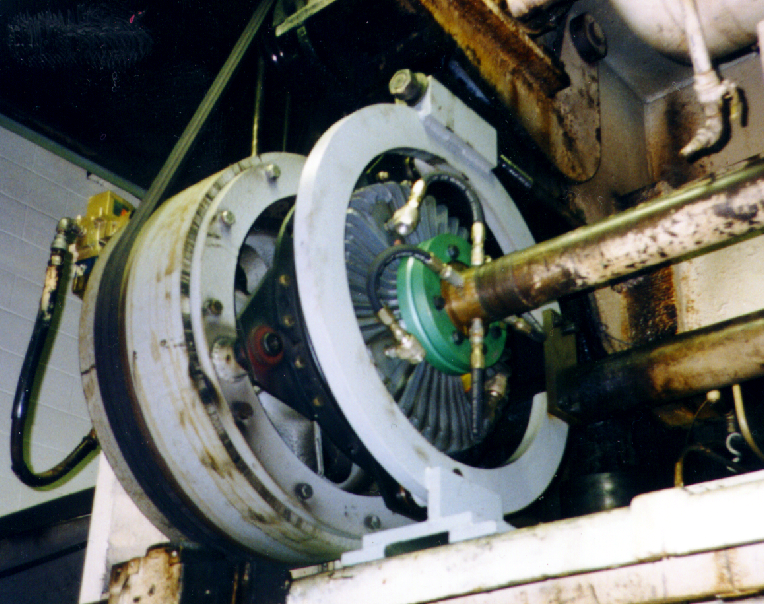

* Wichita Clutch – Air Clutches, Spring Set Brakes and Combination Clutch/Brakes

* Industrial Clutch – Air Clutches, Spring Set Brakes and Hydraulic Combination Clutch/Brakes

* Herion – Hydraulic Combination Clutch/Brakes

* Kobelt – Caliper Disk Brakes

* Mach III – Small Air Clutches, Brakes and Torque Limiters

ABOUT TORQUE INC:

Torque Inc. has represented Wichita Clutch for 60 years and continues to provide Heavy Duty Clutches/Brakes to the Metal Forming, Coil Processing, Converting, Printing, Marine, Mining and other heavy industries. Our staff of expert application engineers and professional customer service representatives is available to support you with:

- Technical Support

- New Application Engineering

- Retrofit Engineering

- Genuine Parts from our Extensive Inventory

- Clutch/Brake Rebuild Service

- New Units from our Extensive Inventory