Most industrial Air Clutch/Brake applications have Quick Release Valves (QRV or Quick Exhaust) engineered into the air system to provide rapid exhaust of the air pressure by providing a large exhaust port right at the clutch or brake. Air systems with properly engineered, installed and maintained QRV’s, offer significantly improved operation of clutches and brakes in high cycle applications (single stroke operation of a press).

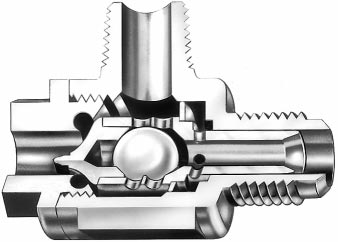

To properly engineer, install or maintain a system with QRV’s, it’s important to understand what they are and how they work. The most popular QRV’s supplied by Torque Incorporated are:

The Wichita QRV’s are engineered to mount to the Airtube Spuds to provide rapid exhaust from the Wichita Clutch/Brake. The Industrial Clutch QRV – Rotary Seal is engineered to mount to the Cylinder of an Industrial LK Clutch (and Verson clutches) to provide rapid exhaust and controlled clutch engagement by modifying the orifices in the poppet assembly.

Quick Release Valve (QRV or Quick Exhaust) operation is fairly easy to understand, the basic schematic using a Quick Release Valve (QRV or Quick Exhaust) is below:

When the 3/2 valve is engaged to pressurize the clutch/brake, the air pressure at P1 is greater than the air pressure at P2 causing the poppet in the QRV to close the exhaust port, allowing air to flow from the supply to the clutch/brake. When the 3/2 valve is released, removing pressure from the Clutch/Brake, the air pressure P1 is less than the air pressure P2 causing the poppet in the QRV to seal off the input. This allows the the air to exhaust the clutch/brake directly through the QRV.

While the operation of QRV’s is very simple, we see many issues with their application and installation.

- When QRV’s are installed it is critical that the volume of air between the 3/2 valve and QRV is small enough so P1 remains significantly lower than P2 until the clutch/brake is fully exhausted.

- QRV’s should never be installed in series.

- QRV’s are typically only used on Clutches in Stamping Press applications when a separate clutch and brake are used.

QRV’s have wearing parts, their operation should be checked regularly as part of your Preventative Maintenance Program or if you experience erratic stopping or an increase in stop time. Checking operation can be accomplished by simply cycling the air system and monitoring the QRV to ensure there is a strong puff of air when the system should exhaust. If the QRV does not respond with a strong blast of exhaust, it should be replaced or rebuilt depending on style.

It is best to run QRV’s without mufflers, if possible, the mufflers tend to slow the exhaust and trap air system contaminates in the QRV. If you need to abate the noise created by the QRV, use a muffler with a large surface area to not restrict the exhaust flow.

Your Torque Inc. local Sales Engineer is an expert with QRV’s and is available to help you with any issues with your clutch/brake air system design, installation, operation and maintenance. If you have any questions give us a call, we are happy to be of service.