There are many methods to mount a Clutch/Brake hub to the shaft of a Stamping Press or other heavy machinery. Torque Inc will help you pick the best type of connection for your application. The following is a summary of the benefits and limitations of the various methods:

Key with clearance

Using a clearance fit between the hub and the shaft while and hand fitting the key (or two keys) is the most common method. Clearance of a couple of thousandths of an inch with line/line for the keyway is typical. This connection will likely gradually get loose at some point in time, is likely the most common type used on a press.

Key with interference

Adding a slight interference with a hand fit key is a more permanent solution, albeit requiring a modest heating of the hub (to about 250- 300 degrees F through via oil bath, oven or induction heater). Typical fit of line/line to .001”/.002” for shaft size of 6”.

Key with heavier interference

Increasing shrink to .0005” per inch of diameter (ie. .003” interference for 6” bore ) is achievable with a 300-400 degree heat and dry ice of the shaft. This fit is recommended for high shock load/high reversing loads like shears and high stripping force dies, cold forging etc. Care must be taken not to end up with too tight a fit over a key, in that this can cause the hub to split through the keyway. Heavy interference fits are difficult to remove without damaging the shaft/bore interface.

Heavy Interference without key

Using a .001” per inch of shaft diameter interference (ie. .006”-.009” shrink for a 6” shaft) , or more, can often times gain enough torque to drive without a key or supplemental locking device. However, we do not recommend retrofitting using this method due to the following problems, indluding but not limited to:

1. Precise material specifications are required,

2. Precise machining is required,

3. Installation is tricky

4. Removal does damage to the shaft and hub bore.

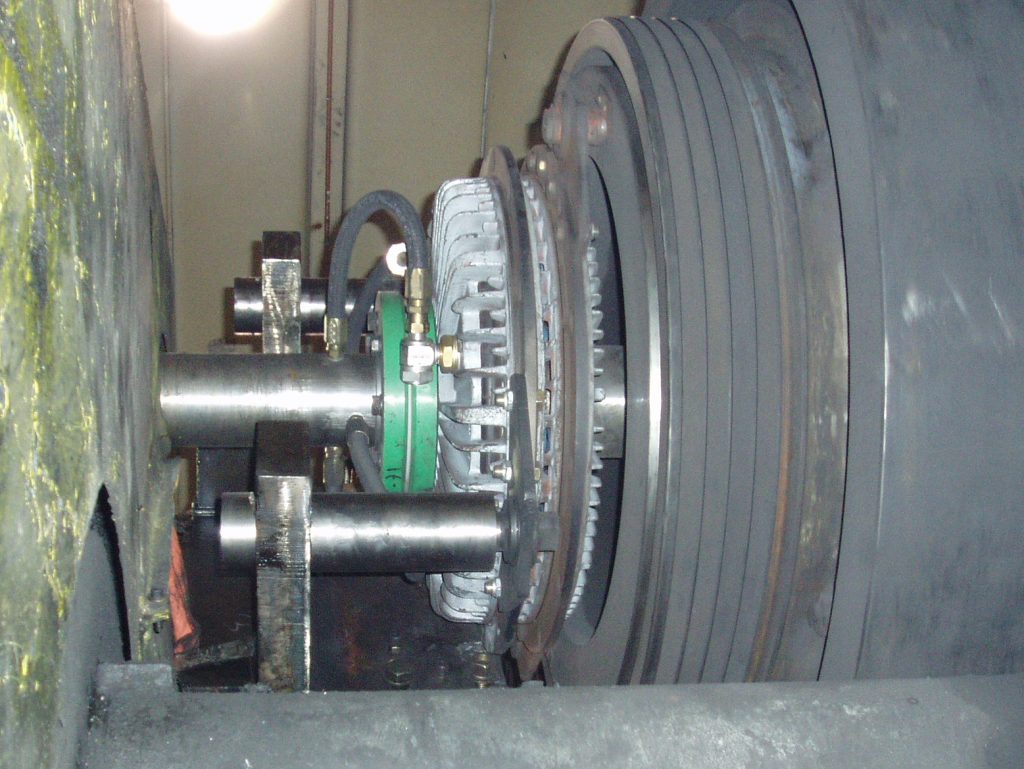

The best system is a Engineered Locking Element without a key

Using an engineered locking device such as a Ringfeder, Climax or Bloc creates the advantages of heavy inference shrink fit connection (ie. No backlash ever, removability, ease of assembly and strongest possible shaft and hub design due to no stress risers from keys) without the disadvantages. Some applications are hard to retrofit due to space and material issues. These devices require proper dimensions and installation procedures and torque instruction be followed in order to function properly. However the devices have a 100% success rate when properly engineered and installed (in fact they frequently can carry more torque than the shaft itself can!) .

There are two primary types of keyless locking devices.

The “shrink disc” goes outside of a hub extension and squeezes the hub to the shaft. Advantages are a infinite choice of shaft sizes (ie. Can match any existing shaft assuming it is round and finished properly) and has a relatively high torque rating. Material can be cast iron or steel

The internal “locking assembly “ is sometimes easier to fit in (goes inside existing hub) but can only fit a finite number of standard shaft sizes and requires an adequate OD to provide enough strength the keep hub from cracking. Material required to be steel or steel sleeved cast iron.

- Proper selection of either version of an engineered locking element requires the qualified engineering assistance that Torque Inc. can provide to insure a successful installation.

- Often the cost of the device is offset by the reduction in labor/machining cost associated with putting a connection together!