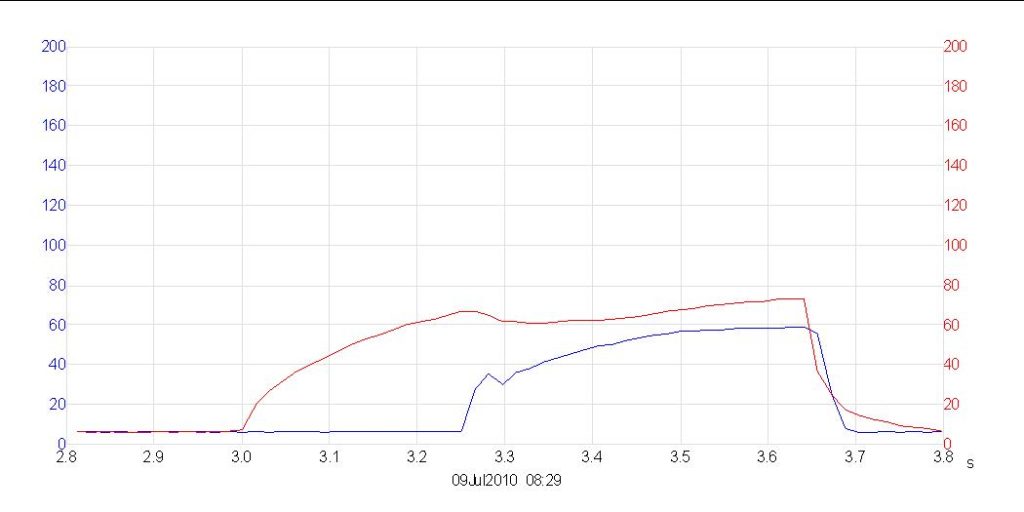

Many times when Torque Inc. gets called to help customers with Clutch and Brake problems we find the root cause is an inadequate air system starving the clutch and/or brake. Below is an excellent example of this phenomenon with a separate Clutch/Brake application on a high speed shear.

The clutch is the Blue Pressure Line and the Brake is the Red Pressure Line. You will notice it takes over 200 msec to get the brake to 60 PSI and the same time for the clutch to reach 50 PSI. A larger surge tank will greatly reduce this time and allow much more consistent operation and better tonnage higher in the stroke in press or shear applications. You will also notice there is no overlap during engagement because of a timer in the controls delaying the clutch valve firing. There is considerable overlap during disengagement, which was corrected by adding another timer below:

Notice how the Blue pressure curve of the clutch now drops off quickly before the brake sets. In addition to being done with a timer in the control system, Torque Inc. application engineers can accomplish this same function with a properly designed Herion Press Safety Valve system using two XSz valves and adjusting the timing in the pilot circuit.